Katana Cloud Inventory Review: A Deep, Honest Look From a Business Operator’s Perspective

Well, let’s start with something most business owners won’t admit out loud: inventory management is rarely the dream part of entrepreneurship. No one wakes up excited to reconcile stock levels or chase missing components. But when inventory goes wrong, it goes really wrong — missed orders, angry customers, stalled production, wasted cash.

That’s exactly the space where Katana Cloud Inventory positions itself. Not as flashy software that promises the world, but as a practical, modern system designed to bring order to businesses that are growing faster than their spreadsheets can handle.

In this review, I’m not just listing features. I’m walking you through what Katana feels like in real use — the good, the not-so-great, and the moments where it quietly proves its value.

If you run a manufacturing business, a product-based brand, or any operation juggling raw materials and finished goods, this one’s for you.

The Core Idea Behind Katana

At its heart, Katana is a cloud-based inventory and manufacturing management platform built for small to mid-sized businesses. Not global conglomerates. Not factories with six layers of approval. Real businesses run by real people who want answers now, not next week.

The philosophy is simple: everything should be visible, connected, and updated in real time.

Inventory isn’t static. Production isn’t isolated. Sales don’t happen in a vacuum. Katana treats your business like a living system instead of a pile of disconnected data.

That sounds abstract, but in practice it means fewer surprises — and fewer “How did this happen?” moments.

Real-Time Inventory: Where Katana Starts Shining

Let’s talk about inventory visibility, because this is where most systems either shine or collapse under pressure.

With Katana, inventory updates instantly. Not later. Not after a sync. Not when someone remembers to refresh a spreadsheet.

Imagine you’re selling custom backpacks. Each one requires specific materials — fabric, zippers, buckles, labels. The moment a customer places an order, Katana reserves those materials automatically.

That reservation matters.

It means the system doesn’t pretend you still have stock available when it’s already promised elsewhere. It’s honest. Sometimes brutally so — but honesty saves money.

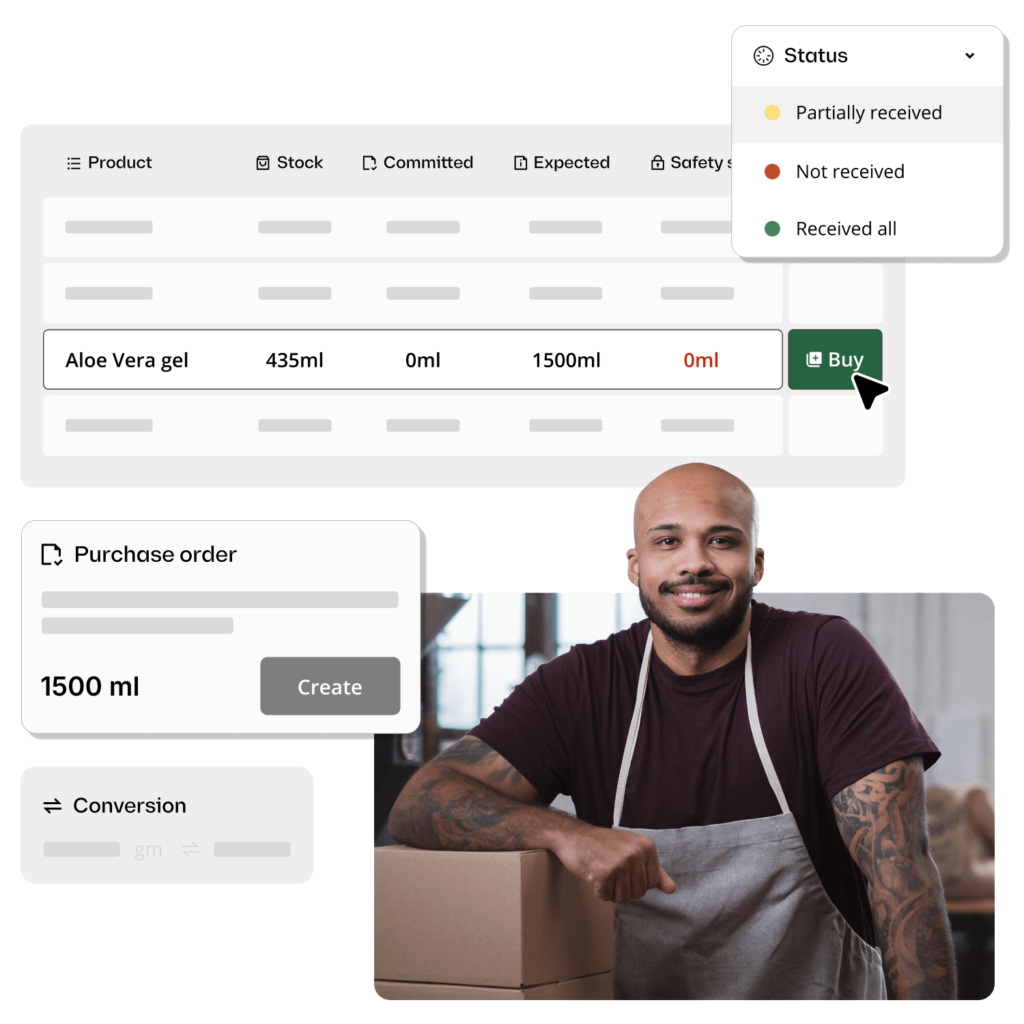

You see:

- What’s in stock

- What’s committed

- What’s expected

- What’s missing

No illusions. Just reality.

Manufacturing Management Without the ERP Nightmares

Traditional manufacturing software often feels like it was designed in another decade. Heavy menus. Endless setup. Terminology that makes you feel like you need a consultant just to click “Start.”

Katana takes a refreshingly different approach.

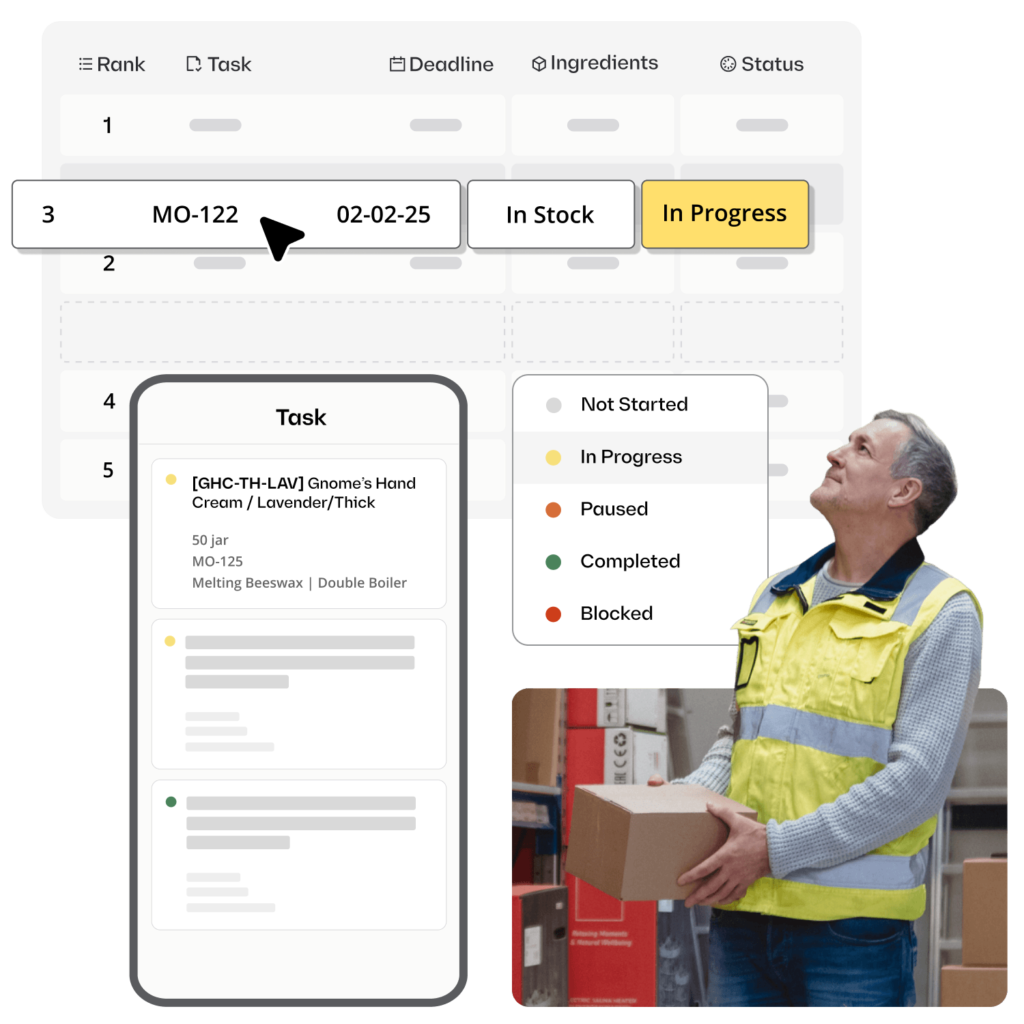

Production planning is visual. You see production orders laid out clearly — what’s planned, what’s in progress, and what’s blocked due to missing materials. It’s like having a whiteboard that updates itself and never gets erased by accident.

Bills of Materials (BOMs) are central here. You define what goes into a product once, and Katana handles the math forever after. Change a component? The system adjusts inventory and production requirements instantly.

This is where things start to feel… calmer.

Instead of reacting to problems, you see them coming.

Production Scheduling That Respects Reality

One of the most frustrating things in manufacturing is planning production based on wishful thinking. You know the type — schedules that look great on paper but ignore material shortages, machine limits, or labor constraints.

Katana doesn’t play along with fantasies.

If materials aren’t available, production doesn’t magically proceed. It pauses. It flags the issue. It forces a decision. That might feel annoying at first, but it prevents disasters later.

Think of it like a GPS that reroutes you early instead of letting you drive into traffic.

Sales Orders and Inventory: Finally in Sync

Here’s a common scenario.

Sales sells something.

Operations panics.

Inventory scrambles.

Customers wait.

Katana fixes this disconnect by tying sales orders directly to inventory and production.

The moment an order enters the system:

- Inventory is reserved

- Production requirements are calculated

- Purchasing needs become visible

There’s no “we’ll figure it out later.” The system figures it out immediately.

This alignment alone can transform internal communication. Sales stops overpromising. Operations stops firefighting. Everyone works from the same reality.

Purchasing That Actually Makes Sense

Purchasing is often reactive. You run out of something, then rush to reorder it, often paying more than necessary.

With Katana, purchasing becomes proactive.

When materials dip below defined thresholds, the system highlights shortages clearly. You can generate purchase orders directly from those insights instead of hunting for numbers.

It’s not glamorous — but it’s efficient.

And efficiency compounds.

The Interface: Calm, Modern, and Surprisingly Human

Let’s be honest. Many business tools look like they were designed by engineers who never talked to users.

Katana feels different.

The interface is clean. The layout is logical. You don’t feel lost clicking around. Most users can get productive quickly, which matters more than fancy features buried under complexity.

This is software you can actually hand to your team without a week-long training session.

Integrations: Letting Systems Talk Instead of Fight

Modern businesses don’t live inside one tool.

Katana integrates smoothly with accounting platforms, eCommerce stores, and automation tools. Orders flow in. Inventory updates. Financial data stays aligned.

The less manual work you do, the fewer mistakes slip through.

And mistakes in inventory are expensive.

Real-Life Growth Scenario: From Chaos to Control

Let’s ground this in a real-world example.

A small electronics brand starts with manual tracking. At first, it’s fine. Then sales grow. Components increase. Assembly becomes complex.

They adopt Katana.

Suddenly:

- They know exactly how many units they can build

- Production delays become visible early

- Inventory cash flow improves

Growth becomes structured instead of stressful.

That’s the difference between surviving growth and managing it.

Pricing: The Honest Conversation

Now, let’s talk about money.

Katana is not the cheapest option on the market. And that’s intentional.

Pricing is tiered, typically based on:

- Number of users

- Feature depth

- Integration access

- Scale of operations

For very small businesses, it may feel like a stretch. But for companies already losing money to inefficiencies, the math often works out fast.

It’s an investment — not an impulse buy.

Pros of Katana Cloud Inventory

The advantages stack up quickly.

Katana offers real-time inventory accuracy, intuitive manufacturing workflows, seamless sales alignment, and a user experience that doesn’t fight back.

It reduces human error, supports growth, and replaces guesswork with data.

Cons of Katana Cloud Inventory

No system is perfect.

Pricing may be high for very small teams. Customization, while solid, isn’t infinite. Extremely complex enterprises may eventually outgrow it.

But for its target audience, these are manageable trade-offs.

Who Katana Is Best For

This software shines for:

- Small to mid-sized manufacturers

- Product-based brands

- Businesses moving beyond spreadsheets

- Teams that want visibility without chaos

If inventory mistakes cost you sleep, Katana is worth serious consideration.

Final Thoughts: Is Katana Worth It?

Actually, yes — if you’re ready.

Katana doesn’t promise miracles. It promises clarity. And clarity is powerful.

It helps you see your business as it truly is — not as you hope it might be. That honesty leads to better decisions, smoother operations, and sustainable growth.

Sometimes the best software doesn’t shout.

It simply makes everything else quieter.

Read Our another Review: QuickBooks Review 2026: King of Small Business Accounting